Text begins from here.

Panasonic to Release Ceiling Mount Type 'ziaino'

Hypochlorous Acid Indoor Antibacterial Deodorizer

Hypochlorous Acid Indoor Antibacterial Deodorizer

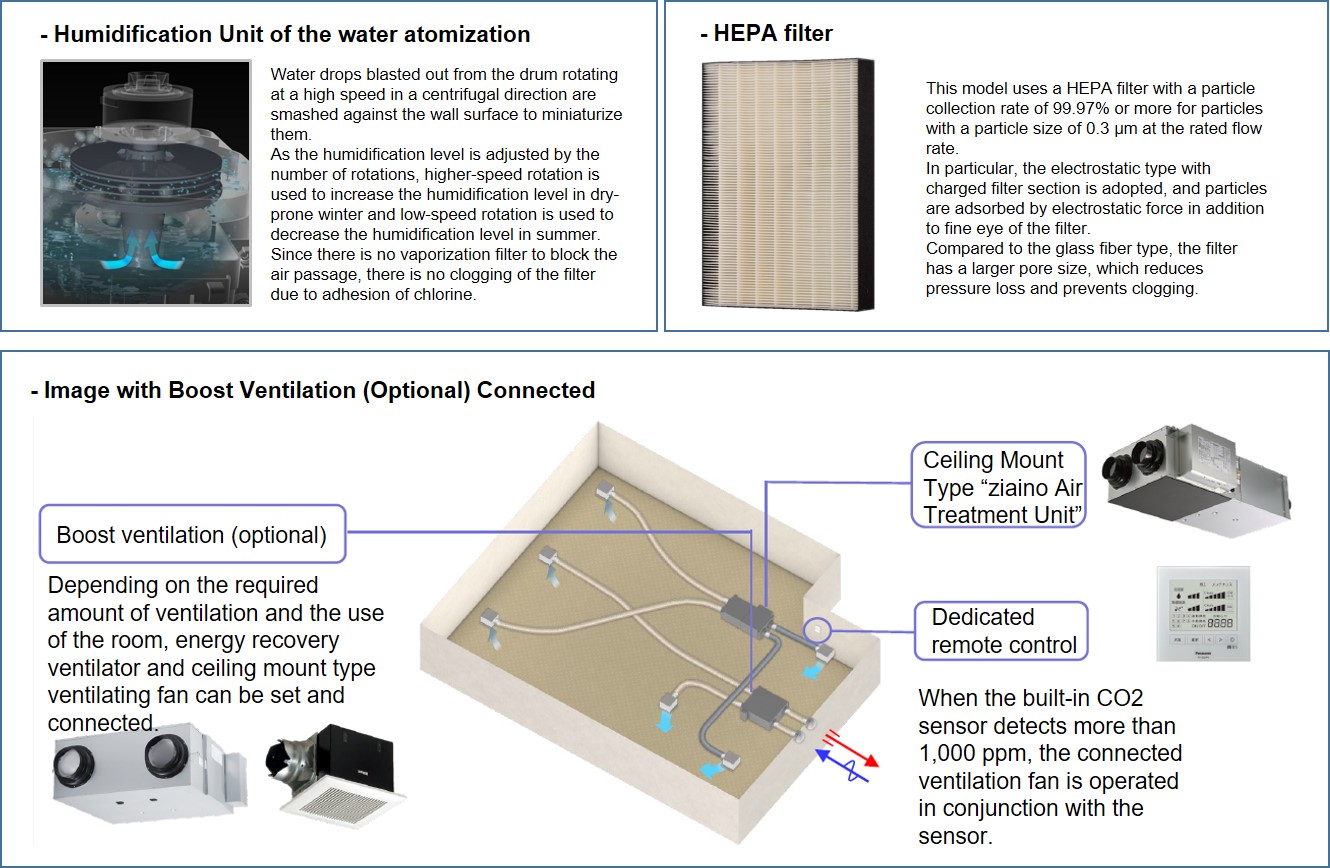

- The new "ziaino Air Treatment Unit" designed for non-residential buildings further improves air quality by adding the humidification function of the water atomization

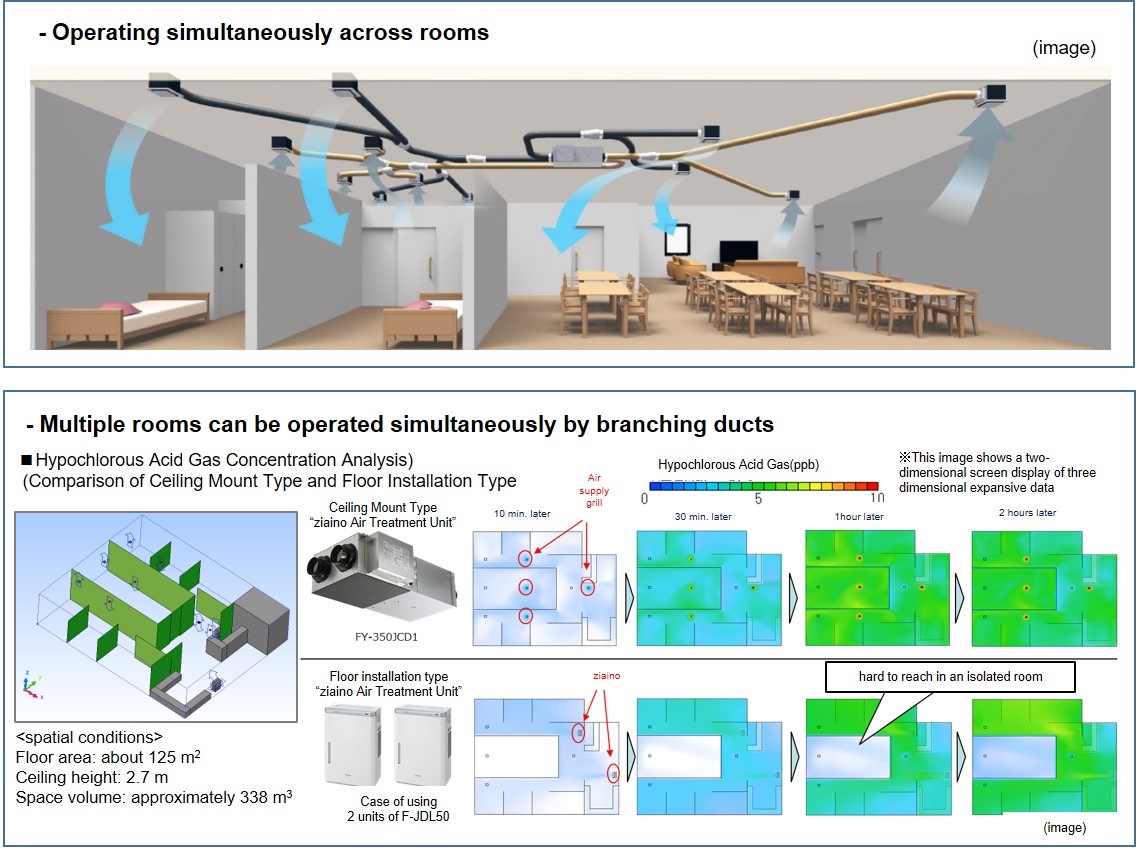

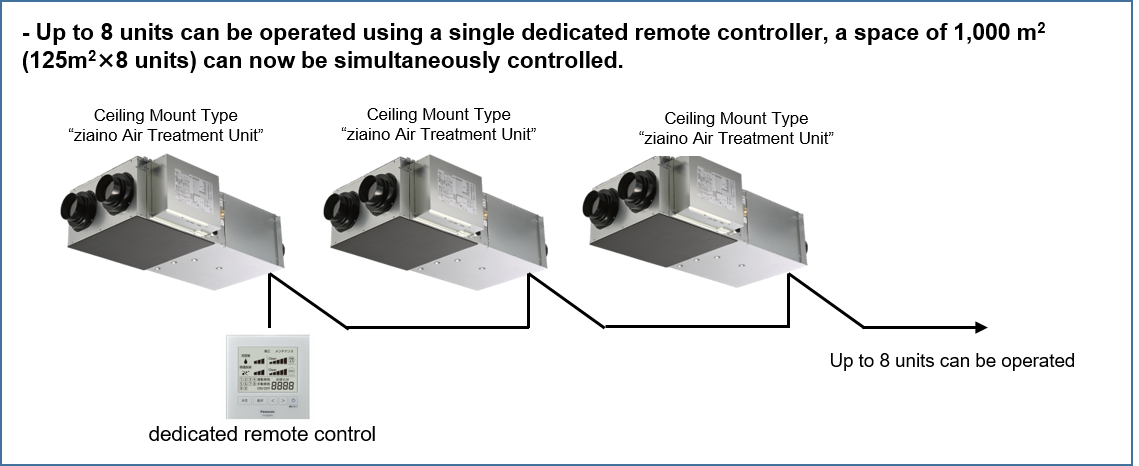

- This ceiling mount type unit, without taking up floor space, can simultaneously serve multiple rooms.

Ceiling Mount Type "ziaino Air Treatment Unit"

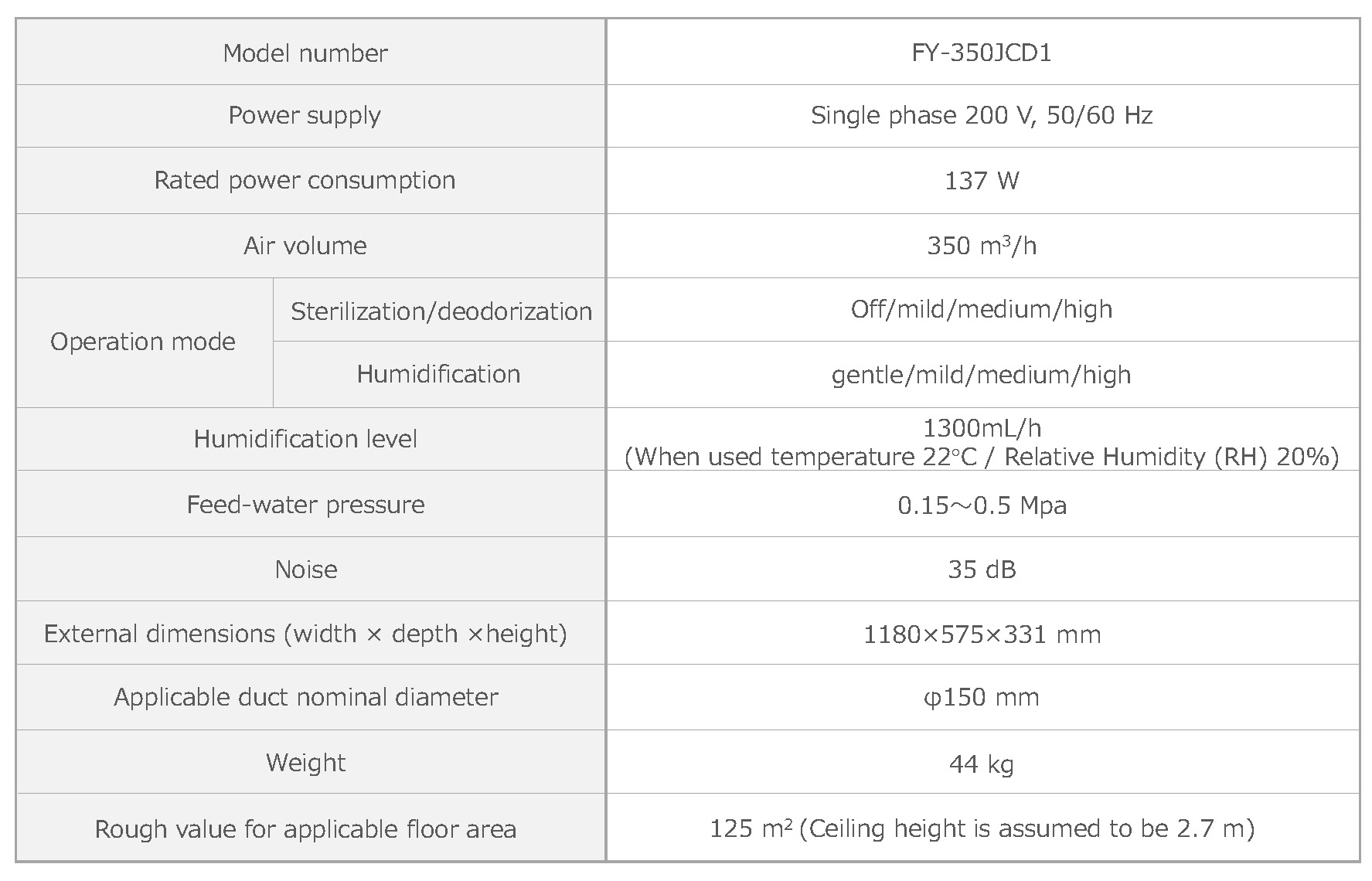

Panasonic Ecology Systems Co., Ltd. will release the Ceiling Mount Type "ziaino Air Treatment Unit," which has strong sterilizing and deodorizing capacity by utilizing hypochlorous acid technology (*1) as well as the new humidification function provided by water atomization technology (*2) on April 1, 2022 in Japan.

The hypochlorous acid technology used in "ziaino" has a history of more than 30 years. Panasonic applied its filter technology and other technology to the hypochlorous acid technology that had been cultivated by Sanyo Electric since 1987, and in 2013, launched "ziaino," which specializes in sterilization and deodorization. Over the eight years since then, the total number of shipped units reached 300,000 in August 2021. It is used in wide range of facilities including medical, educational, and nursing care institutions, and its powerful sterilizing and deodorizing capabilities have been highly evaluated by customers. Lately, consideration for sterilization measures in spaces where a large number of people gather has become more important than ever. In addition, in nursing homes, not only sterilization but also odor removal is becoming an issue. Furthermore, interests in air quality has increased, and the importance of appropriate ventilation and humidification has been reconsidered.

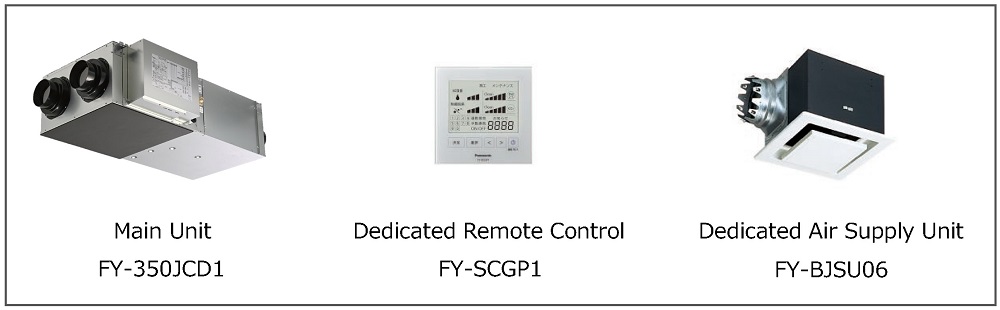

The new product adds humidification, dust collection function by HEPA filter and boost ventilation (*3) (optional). It is a built-in type installed on the ceiling which does not take up much space and thus keeping the floor neat. There is no need to install a main unit in each room but instead the system can be operated simultaneously in multiple rooms because clean air is supplied into the room from the dedicated duct. In addition, as it can automatically supply and drain water, continuous operation is now possible without troublesome water supply and drainage work (*4).

Panasonic will continue to contribute to the creation of a more secure and comfortable air environment not only in residential areas but also in non-residential spaces where an unspecified, large number of people gather.

Features

1. The new "ziaino Air Treatment Unit" further improves air quality of non-residential spaces by adding the humidification function of the water atomization

2. As it is a built-in type installed on the ceiling, space will not be taken up and the floor is kept neat. It can operate simultaneously across rooms.

3. Automatic water supply and drainage eliminates daily maintenance (*4).

Notes:

*1: Technology that electrolyzes salt water to produce hypochlorous acid

*2: Technology to reduce the size of water droplets spouted in the centrifugal direction from a high-speed rotating drum by hitting them against a wall surface

*3: When the sensor detects CO2 levels exceeding 1000 ppm, an interlocking ventilation fan will operate for 30 minutes.

*4: Annual replacement of consumables and maintenance are required.

[Features in Detail]

1. The new "ziaino Air Treatment Unit" further improves air quality of non-residential spaces by adding the humidification function of the water atomization

This new product reduces excessive dryness in winter with the added water atomization method humidification function for controlling humidification level. The water atomization method can humidify air efficiently with a small amount of water and is free from clogging caused by chlorine adhesion or maintenance of the humidifier unit. The product is also equipped with a HEPA filter which prevents pollen and dust entering the room so to make the space more comfortable. The dedicated remote controller has a built-in CO2 sensor. The product has a boost ventilation function to operate the interlocked ventilation fan (separately sold) for 30 minutes when CO2 concentration exceeds 1000 ppm. This enables the unit to operate according to the conditions when the ventilation amount is insufficient due to an increase in people in the room.

2. As it is a built-in type installed on the ceiling, space will not be taken up and the floor is kept neat. It can also operate simultaneously across rooms.

Users of the conventional "ziaino" for industrial use from medical institutions and nursing homes have been satisfied with its sterilizing and deodorizing performance. On the other hand, the floor installation type was only effective in the space in which it was installed, and some said that the installation in each room was quite a burden. The main unit of the new product is installed in the attic above the ceiling and it supplies clean air to the room via dedicated duct, up to eight air inlets (SA) and air return openings (RA) are placed at optimum positions to efficiently circulate air. By branching the duct, up to eight air inlets (SA) and air return openings (RA) can be installed respectively. So, a single unit can disinfect and deodorize multiple rooms. Furthermore, as up to eight units can be operated using a single dedicated remote controller, a space of 1,000 m2 (125 m2 × 8 units) can now be simultaneously controlled.

3. Automatic water supply and drainage eliminates daily maintenance

As tap water pipes are connected to the main unit and water is supplied and drained automatically, daily work to supply water, drain water, or add salt into the tank is no longer required.

For maintenance, salt water, which is required for producing hypochlorous acid, must be refilled (by replacement of a salt pouch) and the HEPA filter must be cleaned once a year. Some parts including the HEPA filter and electrode unit must be replaced every two years.

(Maintenance with the replacement of the motor and other parts with spare parts is required every five to ten years.)

Sub Menu begins from here.